| Name | Technical Data | Name | Technical Data |

| Ice production | 10ton/day | Cooling tower power | 1.5KW |

| Refrigeration capacity | 56034 Kcal | Water pump power of cooling tower | 3.7KW |

| Evaporating temp. | -20℃ | Standard Power | 3P-380V-50Hz |

| Condensing Temp. | 40℃ | Inlet water pressure | 0.1Mpa-0.5Mpa |

| Total Power | 46.3kw | Refrigerant | R404A |

| Compressor Power | 40KW | Flake ice Temp. | -5℃ |

| Reducer Power | 0.75KW | Feeding water tube size | 1" |

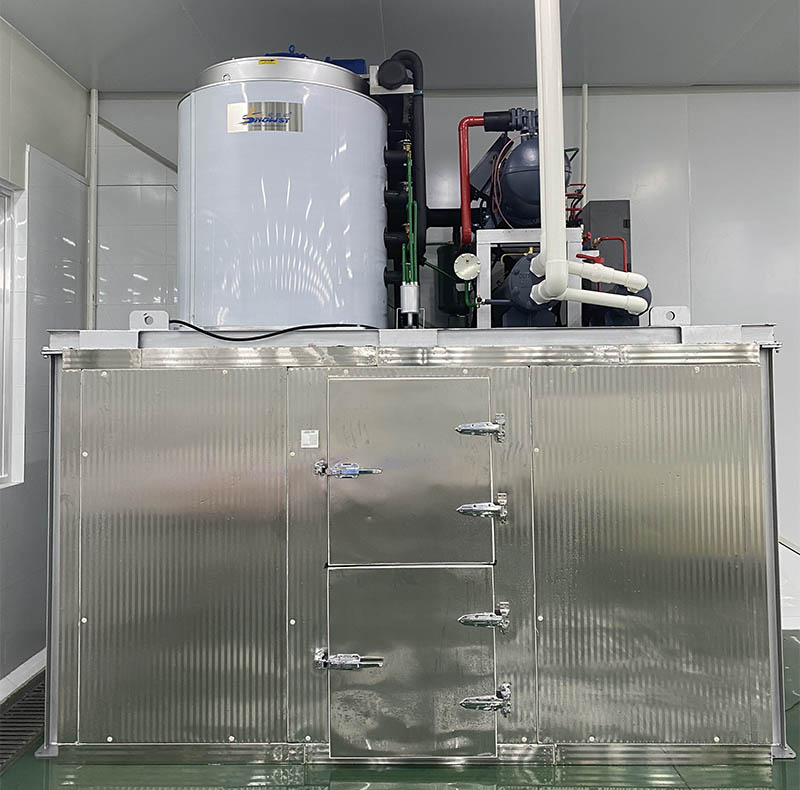

| Water pump Power | 0.37KW | Dimension of flake ice machine | 3320×1902×1840mm |

| Brine Pump | 0.012KW | Ice storage room capacity | 5Ton |

| Net weight | 1970kg | Dimension of ice storage room | 2500×3000×2000mm |

Technical Data Of Flake Ice Machine

FAQ

1. Questions before quotation A. Would you make ice from seawater, saltwater or freshwater? B. Where and when would the machine be installed roughly?The ambient temperature and water inlet temperature? C. What’s the power supply? D. What is the application of the flake ice produced? E. Which cooling mode would you prefer to? Water or air ,Evaporative cooling? 2. Installation & commissioning A. Installed by customers according to the manuals, online instructions and live video conference of ICESNOW. B. Installed by ICESNOW engineers. a. ICESNOW would arrange 1~3 engineers based on the projects to the installation sites for the final supervision of all installations and commissioning. b. Customers need to provide local accommodation and round-trip ticket for our engineers and pay for the commissions. US Dollars 100 per engineer per day. c. Power, water, installation tools and spare parts need to be ready before ICESNOW engineers arrive. 3. Warranty & Technical support A. 1 year after Bill of Lading date. B. Any failure occurred within the period due to our responsibility, ICESNOW will supply the spare parts for free. C. ICESNOW provide full technical support and training courses after equipment installation and commissioning. C. Permanent technical support & consultation all life long for the machines. D. Over 30 engineers for instant after-sale services and more than 20 are available for serving overseas. 365 days X 7 X 24 hours phone / EMAIL assistance 4. Failure Claim procedures a. Detailed written failure description is required by fax or by mail, indicating the relevant equipment information and detailed description of failure. b. Relevant pictures are required for failure confirmation. c. ICESNOW engineering and after-sales service team will check and form a diagnosis report. d. Further trouble-shooting solutions will be offered to customers within 24 hours after receiving the written description and picturesInternational Brand famous components

| Name of Components | Brand Name | Original Country |

| Compressor | Screw Hanbell | Taiwan |

| Ice Maker Evaporator | ICESNOW | China |

| Water cooled condenser | ICESNOW | |

| Refrigeration components | DANFOSS/CASTAL | Demark/Italy |

| PLC Program control | LG (LS) | South Korea |

| Electrical components | LG (LS) | South Korea |

Advantages of Icesnow flake ice machine

1. Microcomputer Intelligent Control: the machine using world famous brand components. Meanwhile, it can protect the machine when there are a water shortage, ice full, high/ low-pressure alarm, and motor reversal. 2. Evaporator drum: use stainless steel 304 or carbon steel chrome for the evaporator drum. The scratch-style system of inside machine ensures constant running at the lowest power consumption, exquisite welding, and processing technology ensures high-efficient heat transfer and energy saving. 3. Ice skates: Spiral hob with small resistance and low consumption, ice making evenly without noise 4. Refrigeration unit: main components all from the leading refrigeration technology countries: the United States, Germany, Japan, etc. 5. Microcomputer intelligent control: the machine is using PLC control system with world famous brand components, which control the whole ice making process, meanwhile it can protect the machine when there are water shortage, ice full, high/ low-pressure alarm, and motor reversal in order to guarantee the machine run stable with fewer faults.